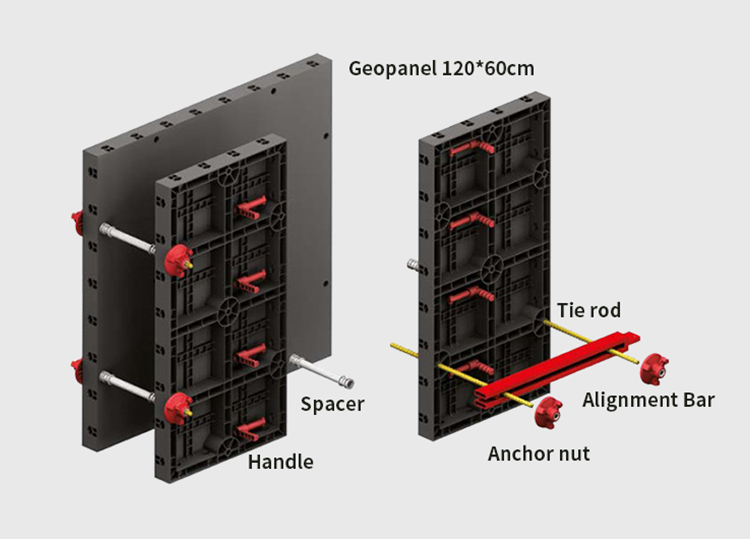

–Universal forming applications are widely used in walls, fences, enclosures, foundations, basements, doors and windows, elevator shafts, swimming pools, and floor slabs, walls, columns, beams, etc. –Save time and labor costs with the largest panel (1200*600mm ) weighs only 9.7kg so it can be easily handled by manpower and saves crane time.

Long service life and recyclable Modified thermoplastic material and high rib design enhance the strength of the panel, it can be used up to 100 times if cleaned and used properly. It is environmentally friendly and can be recycled by professional recycling plants. –No release agent required Non-water absorption ensures easy stripping of concrete. Eliminates the need for release agents and still produces a flat and smooth concrete finish

Template features:

1. Long service life and high cost performance – the plastic formwork can be reused more than 100 times,Plywood can only be reused 3 to 5 times. Therefore, plastic is more cost-effective.

2. Waterproof – natural material as plastic. It’s me who grumbles and rusts,

Especially suitable for underground and water environments.

3. Interlocking design – no need for release agent, good release effect.

4. Easy to disassemble – the plastic formwork is easy to separate from the concrete

5. Simple installation – light weight, safe to operate, easy to clean and very strong.

6. High quality — good wear resistance, excellent mechanical properties, good impermeability.

7. Recyclable – waste molded boards can be recycled.

We provide reliable products and timely services to construction industry customers all over the world.

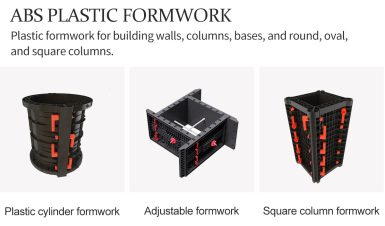

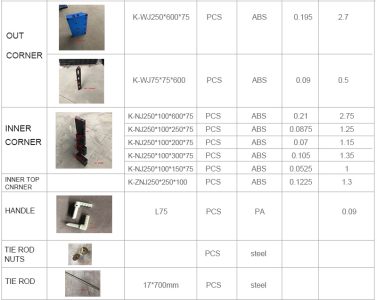

We have a wide range of product lines covering climbing formwork, wall formwork, slab formwork, column formwork, beam formwork, support towers and various scaffolding. We provide a range of solutions to meet customer needs.

high quality

reasonable price

strict delivery time

good after-sales service

16 years of professional manufacturer

1. Long service life and high cost performance – plastic formwork can be reused more than 50 times, while plywood can only be reused 3 to 5 times

Second-rate. Therefore, plastic formwork is more cost-effective.

2. Waterproof – as a plastic material. It is not easy to calculate and does not rust, especially suitable for underground and water environments.

3. Interlocking design – no need for release agent, good release effect.

4. Easy to disassemble – the formwork is easily separated from the concrete.

5. Simple installation – light weight, safe to operate, easy to clean and very strong.

6. High quality — good wear resistance, excellent mechanical properties, good impermeability.

7. Recyclable – waste molded boards can be recycled.