Process characteristics of film-coated board:

1. Select 5-7 years old eucalyptus logs, which have small stutter and good toughness, and select the whole core veneer during rotary cutting;

2. High-quality pine and eucalyptus full-core first-level core boards are used to assemble blank boards. The layers are clear, the surface is smooth, there is no void in the middle of sawing, and the density is 700kg/m3.

3. The surface coating is phenolic resin glue with strong waterproof performance. The core board is made of ammonium glue (a single layer of glue can reach 0.3KG), and it is glued layer by layer, fully bonded, and the bonding strength is increased by 5-10%.

4. The hot pressing pressure is 120% of the theoretical pressure, and it is forbidden to reduce the pressure to preserve the thickness.

Main production specifications: laminated board, small red board, big red board, building wood, etc. The film-coated board has the characteristics of flat and smooth surface, uniform thickness, good waterproof performance, and easy demoulding. After cooking in Buddha water for 120 minutes, it can still meet the bonding strength requirements, and the number of turnovers can reach more than 15 times.

Product Usage:

Uses: Construction templates for bridges, small high-rise buildings, tunnels, railways, etc.

Processing cycle:

Commonly used specifications of laminated panels are usually ordered 7 days in advance, and urgent orders need to be notified 5 days in advance. Generally, factories will stock 10,000 to 20,000 templates of regular specifications to meet the urgent needs of customers.

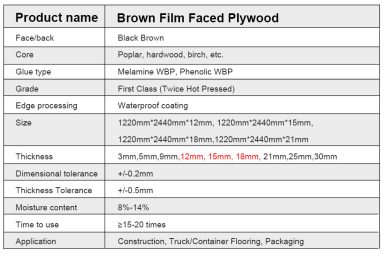

This parameter only represents part of the data, please consult us for details:

Smooth surface

Alcohol paper surface + full core poplar surface +

The bamboo curtain core of equal thickness has been pressed under high temperature and high pressure

Made of uniform thickness and smooth surface

Smooth, easy to remove the film, the film paper is not sticky

Concrete surface, no need for secondary plastering,

Good bonding strength

The bonding strength and adhesion are better, and it will not open when exposed to water

Adhesive layer, turnover times more than 8 times

Earn more money with more use

The quality is stable

24 fine craftsmanship, 3 quality inspections, military style

Optimized on-site management, no one is unqualified

The product flows into the next process, the quality is stable

Sure, the quality is always the same