Aluminum formwork, also known as concrete engineering aluminum alloy formwork, is a new generation of formwork system after plywood formwork, composite steel formwork system, steel frame wood (bamboo) plywood system, large formwork system, and early dismantling formwork system. [8] Aluminum alloy templates are made of aluminum alloy profiles as the main material and are suitable for concrete engineering through mechanical processing and welding processes. They are designed according to a 50mm module and are composed of panels, ribs, main profiles, flat templates, corner templates, and early dismantling devices. The design and construction application of aluminum alloy formwork is an innovation in concrete engineering formwork technology, a promotion of prefabricated concrete technology, and a manifestation of the industrialization of construction technology.

The aluminum alloy template system can be divided into two categories according to different stress modes: tension rod system and tension plate system.

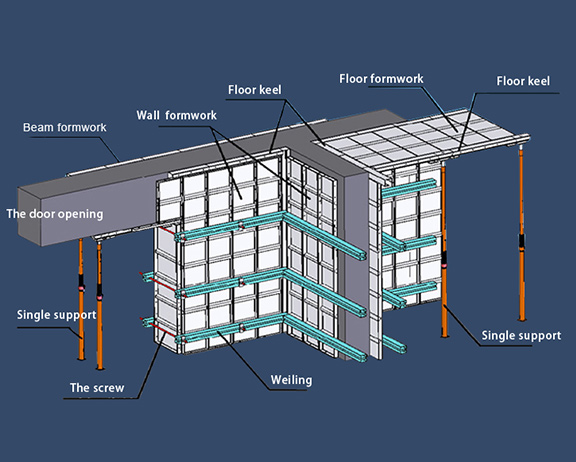

The aluminum alloy template of the pull rod system is composed of a template system, a fastening system, a support system, and a accessory system, and has a complete supporting template system. It is suitable for template systems in different areas such as urban pipe corridors, public buildings, and residential buildings.

The aluminum alloy template of the pull tab system consists of three parts: template system, support system, and accessory system. It has a complete supporting template system and is generally suitable for residential buildings.

The template system is divided into flat templates, corner templates, and components according to their structural form. Among them, corner templates include external corner templates, internal corner templates, and internal corner templates, with components including single inclined aluminum beams, double inclined aluminum beams, early dismantling of floor slabs, and early dismantling of beam bottoms.

The support system is divided into steel support, aluminum support, and other supports according to the material.

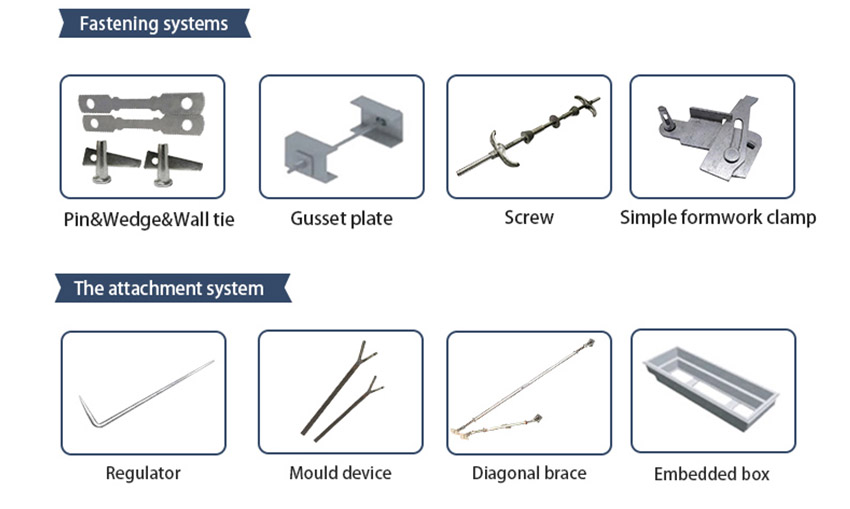

The fastening system is divided into steel back reinforcement and pull sheet reinforcement according to the stress form. The reinforcement components are divided into aluminum back reinforcement, steel back reinforcement, light steel keel back reinforcement, other alloy back reinforcement, square tube back reinforcement, etc. according to the material

The accessory system is mainly composed of bolts, pins, screws, and pullers.