The main material of the ICF module itself is expandable polystyrene EPS foam, with built-in plastic or metal pull joints

pieces. During construction, the ICF module is used to form the shape of the wall, and a small amount of steel bars are placed in the hollow cavity inside the ICF module.

On both sides of the body, support the pillars to prevent tilting deformation, and then fill the interior of the ICF cavity with concrete

In fact, the ICF module played the role of formwork at the time of construction, and played the role of thermal insulation afterwards.

Insulated concrete formwork system (ICF) has the characteristics of simple, convenient and high-efficiency construction, and is not subject to seasonal restrictions; at the same time, polystyrene EPS foam, polyurethane foam and other materials are used, which have high density, high strength and low pollution; the product is systematic and sealed High effect and good durability.

At present, in the global market, the residential sector uses more insulation concrete formwork (ICF). From a regional market perspective, the use of insulated concrete formwork (ICF) accounts for a relatively high proportion in North America. In recent years, the continuous development of the US construction industry and the government’s emphasis on building energy-saving materials have promoted the development of local insulated concrete formwork (ICF) materials.

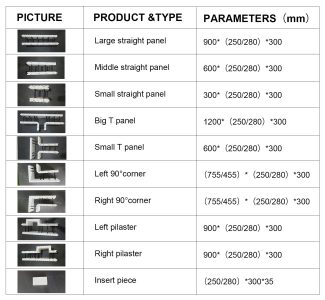

250/280 ICF PARAMETERS:(Please consult us for specific parameters)