The square column buckle is a special button corresponding to the fixed square formwork

Customized matching clamps, the shape has corresponding four elbow single

The galvanized pins are entangled, and one end of the card board is set as a bending knot.

structure, each card board is provided with several identical

Spaced fixing holes, the trapezoidal fixing pins pass through the fixing holes and will

The limit card plate is fixed to form a square column buckle that is easy to install and disassemble

Template fasteners.

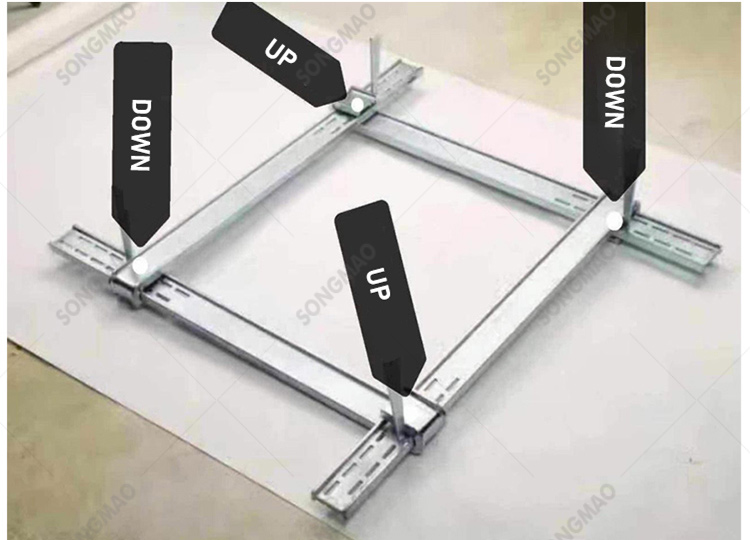

Only two people are needed to conveniently reinforce the building formwork of the square column, increasing the formwork speed by 2-3 times. Place the four pallets opposite to each other in the center of the built square building, then select the corresponding fixing hole according to the size of the square column, and insert the fixing pin at the junction of the two pallets to complete the installation of the reinforcement。

Compared with the traditional reinforcement method, the square column buckle can be completed by two people during the assembly process. The reinforcement of each column takes 20-30 minutes, which is about 5 times that of the traditional reinforcement method. The square column buckle has a permanent service life and is relatively Compared with the traditional reinforcement method, the cost of each column is calculated by removing the formwork in 5 days。

| Adjustable Range (mm) | Material | Total length (mm) | Side panel length(mm) | Intermediate thicness (mm) | Edge thicness (mm) | Width (mm) | |

| Weigh (kg) | |||||||

| 200-400 | 8.0# STEEL | 965 | 5 | 18 | 80 | 15.5 | |

| 400-600 | 8.0# STEEL | 1165 | 5 | 18 | 80 | 24.5 | |

| 500-800 | 8.0# STEEL | 1365 | 5 | 18 | 80 | 26.5 | |

| 500-800 | 10.0# STEEL | 1465 | 8 | 20 | 100 | 50 | |

| 700-1000 | 10.0# STEEL | 1665 | 8 | 20 | 100 | 58 | |

| 900-1200 | 10.0# STEEL | 1865 | 8 | 20 | 100 | 64 | |

| 1100-1400 | 10.0# STEEL | 2065 | 8 | 20 | 100 | 71 | |

| 1300-1600 | 10.0# STEEL | 2265 | 8 | 20 | 100 | 78.8 | |

| 1300-1600 | 10.0# STEEL | 2265 | 640 | 8 | 20 | 100 | 101.71 |

| 1500-1800 | 10.0# STEEL | 2447 | 1000 | 8 | 20 | 100 | 120.92 |

| 1900-2100 | 10.0# STEEL | 2747 | 1200 | 8 | 20 | 100 | 138.22 |

| 2200-2500 | 10.0# STEEL | 3160 | 1900 | 8 | 20 | 100 | 176.28 |

| 2500-3000 | 10.0# STEEL | 3660 | 3000 | 8 | 20 | 100 | 231.64 |

| We also can produce different size of clamp according to your requirement | |||||||

The installation of square column buckle reinforcement is very simple, which can help us save time and reduce construction costs. So what are the advantages of using such a simple installation method?

(1) The process is simple and the operation is convenient. The square column buckle reinforcement is a special custom-made supporting clamp corresponding to the fixed square column formwork. The shape is composed of four elbow single-piece galvanized clamps. One end of the clamp is set as a bending structure. The length of the upper edge of each clamp is There are several fixed holes at the same interval in the direction, and the wedge-shaped fixed pin passes through the through hole and the fixed hole to fix the limit sleeve and the clamping plate, forming a square column formwork reinforcement that is easy to install and disassemble.

(2) Square column buckle The construction period is short, the reinforcement is simple, the speed is fast, the installation and disassembly are convenient, and the turnover speed is fast.

(3) The cost can be reduced by setting reasonable hoop spacing. The square column buckle fastener can conveniently fasten the square column building formwork, the fastening effect is good, and the structure is simple and reasonable; the adjustable limit sleeve can be used with the fixed pin to adjust the fixed size, which is suitable for squares of different sizes. The column construction is convenient and practical, and reduces the cost.

(4) The installation and disassembly of the square column buckle reinforcement system is safe and reliable, and the quality and appearance of the concrete after molding are guaranteed.